+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

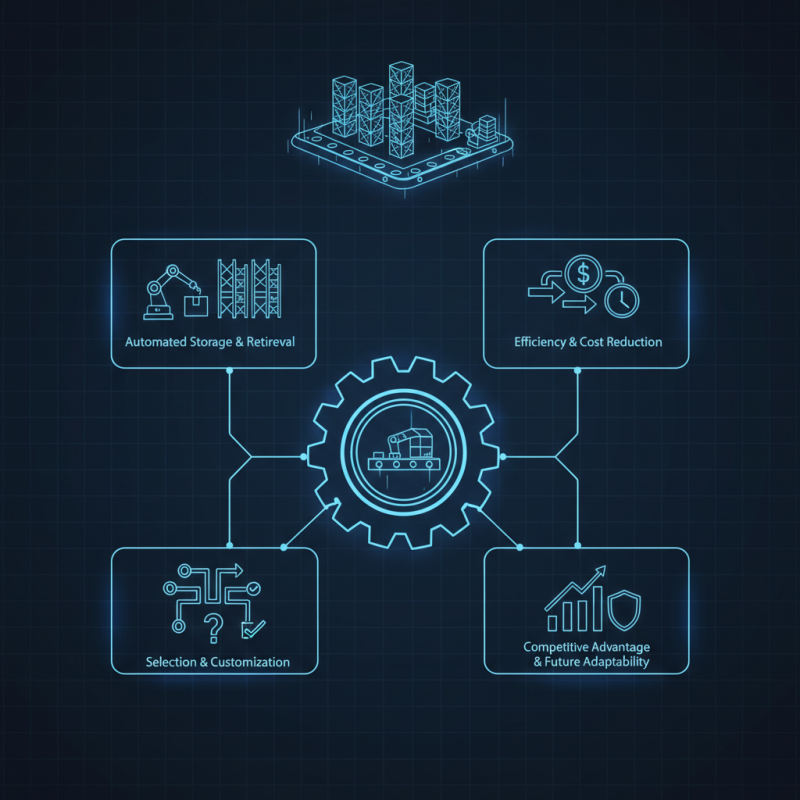

In the world of warehouse automation, ASRS solutions have gained immense popularity. These systems increase efficiency by automating storage and retrieval. Businesses are constantly seeking ways to streamline operations and cut costs. The right ASRS solution can significantly enhance productivity and reduce human error.

Many companies have reported positive results after implementing these technologies. However, selecting the best system is not always straightforward. There are numerous options available, each with its unique advantages and drawbacks. A successful ASRS solution should align with a warehouse’s specific needs.

Investing in warehouse automation is critical for staying competitive. As more companies adopt ASRS solutions, it is essential to evaluate what works best for each business. Understanding the challenges and limitations of these systems can lead to better decisions. The future of warehouse efficiency hinges on the ability to adapt and choose wisely among available options.

Warehouse automation is evolving rapidly, with Automated Storage and Retrieval Systems (ASRS) at the forefront. These systems enhance efficiency by minimizing human intervention. ASRS technologies streamline operations, reduce labor costs, and optimize space. They can operate in various warehouse settings, from small facilities to large distribution centers.

Implementing ASRS can be complex. It requires significant planning and analysis. Understanding your specific needs is crucial. Do you require high-speed retrieval or compact storage? It’s essential to consider different factors influencing your choice.

Tips for successful deployment:

Sometimes, businesses rush to adopt ASRS without fully assessing their requirements. This may lead to wasted resources. Continuous reassessment of technology is vital. Regularly review system performance for ongoing optimization. An ASRS should evolve with the needs of the warehouse to remain effective.

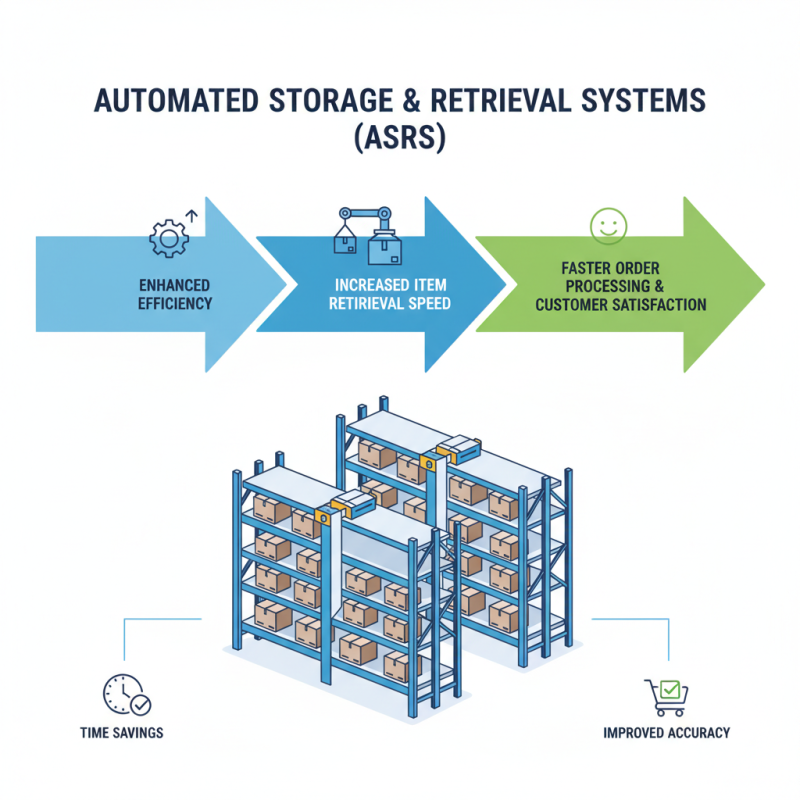

Automated Storage and Retrieval Systems (ASRS) provide significant advantages in modern warehouses. Enhanced efficiency is one of the primary benefits. With these systems, the speed of retrieving items increases dramatically. Warehouses can process orders faster than ever before. This increased speed directly improves customer satisfaction.

Another key benefit is accurate inventory management. ASRS minimizes human error during picking and storing items. This leads to fewer mistakes in order fulfillment. However, implementing ASRS can be challenging. The initial cost may deter some operations. Adaptation requires time and training for staff. Uneven adaptation can result in operational hiccups.

Finally, ASRS systems can optimize warehouse space. These systems can store products in compact configurations. This maximizes vertical space usage and reduces wasted floor area. Yet, it might require a reevaluation of existing warehouse layouts. Sometimes, older structures may not accommodate the technology seamlessly. Balancing these factors requires careful planning and reflection.

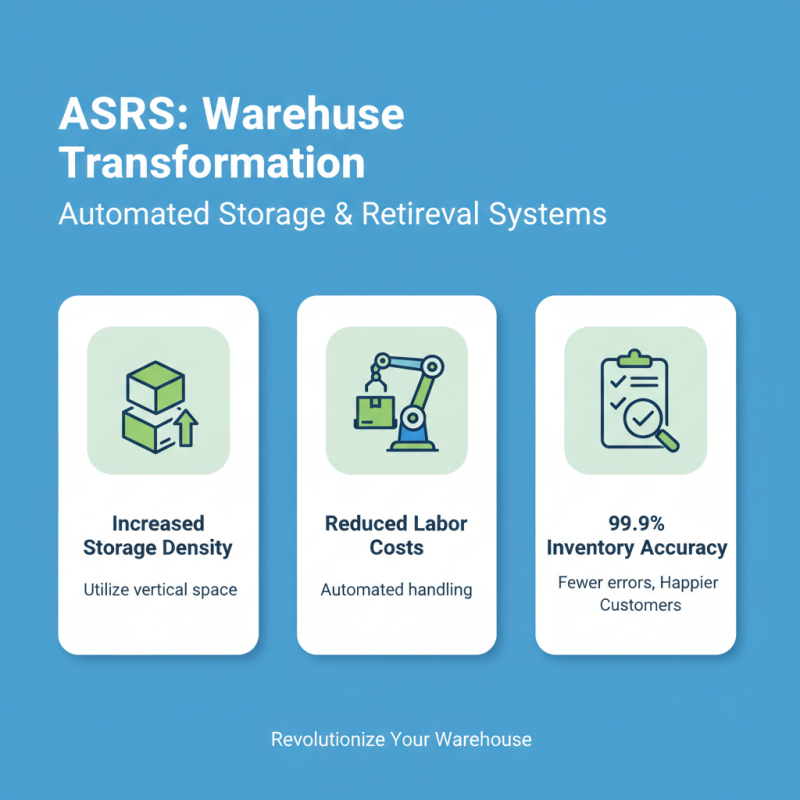

In the realm of warehouse automation, Automated Storage and Retrieval Systems (ASRS) are transforming operations. A recent industry report highlights that deploying ASRS can lead to a 50% increase in storage density. However, the choice of the right solution heavily depends on the specific needs of each warehouse.

When comparing different ASRS solutions, performance metrics play a crucial role. Speed, accuracy, and cost-effectiveness are key factors. Some systems can retrieve items in under 30 seconds, drastically reducing order fulfillment times. However, not every ASRS offers optimal performance across all metrics. Some may excel in speed but fall short in storage efficiency, prompting warehouse managers to reassess their priorities.

Tips: Optimize your layout before implementing ASRS. Ensure your design facilitates the flow of goods. Regularly review your system’s performance data. Do fluctuations in efficiency indicate a need for upgrades? Monitor how well your ASRS integrates with existing technologies to avoid compatibility issues. Be cautious; overlooking these factors can lead to subpar performance and wasted resources.

This chart displays the efficiency and cost associated with the top ASRS solutions in 2026. The efficiency is represented in percentage, while the cost is shown in USD. This visual representation helps in understanding the performance metrics of different systems in warehouse automation.

Automated Storage and Retrieval Systems (ASRS) have transformed warehouse operations. By utilizing ASRS, companies can increase storage density and minimize labor costs. According to a recent report, ASRS can improve inventory accuracy by as much as 99.9%. This precision in operations leads to fewer errors and a better customer experience.

Data shows that implementing ASRS can yield a return on investment (ROI) of 30% or more within the first year. Fast-paced environments benefit from ASRS’s ability to speed up order processing. For example, warehouses equipped with ASRS can reduce order fulfillment time by 20-30%. However, there are challenges. Not every warehouse is suited for ASRS, and the initial investment can be a barrier for some companies.

Training staff to interact with these systems is another concern. Transition strategies need careful planning to avoid disruptions. Infrastructure might not always support the necessary technology upgrades. While ASRS enhances efficiency, companies should evaluate adaptability and workforce readiness. Balancing technology and human labor remains essential as the industry evolves.

Warehouse automation is evolving rapidly. Automated Storage and Retrieval Systems (ASRS) are finding new applications. They help in enhancing efficiency. Companies are now focusing on flexibility and adaptability. Systems can handle multiple tasks seamlessly. This reduces manual errors and speeds up processes.

Future trends in ASRS innovation include artificial intelligence integration. Machine learning algorithms can predict demand patterns. Predictive analytics improve inventory management, too. Real-time data processing allows for quick adjustments. Some systems can reorder stock automatically. However, challenges remain in data integration.

Collaboration between humans and machines is essential. Workers may feel uneasy about technology. Training programs are crucial to ease this transition. As ASRS systems become more sophisticated, human roles will evolve. Developing trust in technology is necessary for smoother operations. Investments in training could bridge this gap.

| Solution Type | Efficiency Gains (%) | Cost Savings (%) | Implementation Time (Months) | Scalability |

|---|---|---|---|---|

| Automated Conveyors | 30 | 20 | 6 | High |

| Robotic Picking Systems | 40 | 25 | 8 | Medium |

| Automated Storage and Retrieval Systems | 50 | 30 | 12 | High |

| Warehouse Management Software | 25 | 15 | 3 | Very High |

| Automated Guided Vehicles | 35 | 22 | 9 | Medium |