+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In today's fast-paced business environment, the efficiency of warehouse operations is crucial for maintaining a competitive edge. A Warehouse Management Tool can be the game changer that businesses need to optimize their inventory management, streamline order fulfillment, and enhance overall operational performance. With the demand for swift delivery and accuracy on the rise, implementing effective warehouse management systems has become more important than ever.

A Warehouse Management Tool not only automates critical processes but also provides real-time data insights, enabling businesses to make informed decisions. By leveraging these tools, organizations can reduce errors, improve inventory visibility, and significantly decrease operational costs. The strategic use of a Warehouse Management Tool leads to greater efficiency, improved customer satisfaction, and ultimately increased profitability.

As businesses continue to grow and evolve, the need for an effective warehouse management strategy cannot be overstated. Integrating a Warehouse Management Tool into your operations equips your business with the necessary capabilities to adapt to market demands, respond to challenges swiftly, and position itself for long-term success. Embracing this technology is not just an option; it is essential for businesses looking to thrive in an increasingly complex supply chain landscape.

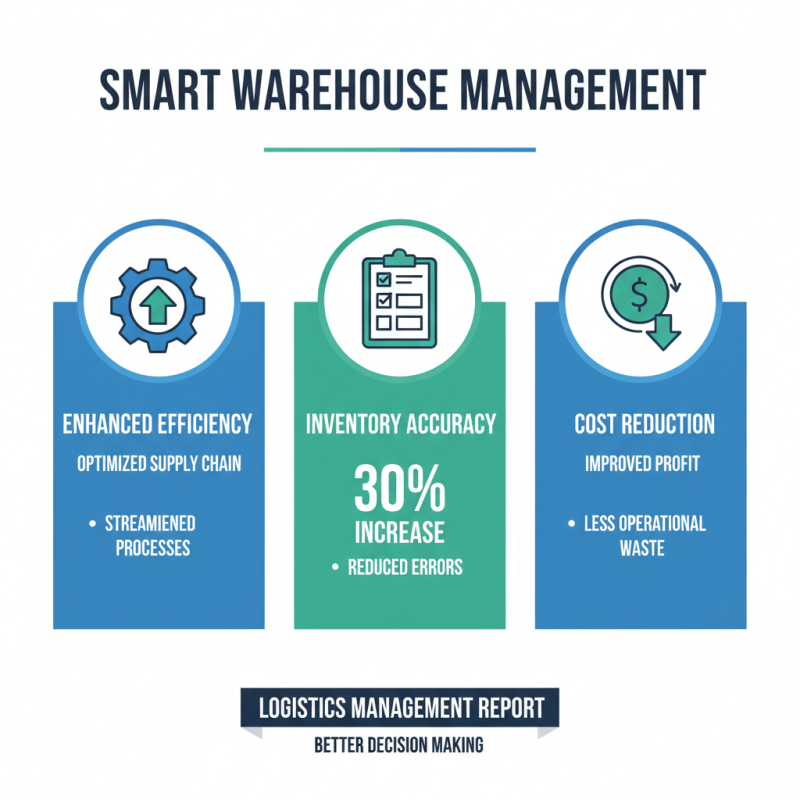

Warehouse management is a critical component for businesses aiming to enhance efficiency and optimize their supply chains. It encompasses the processes and systems used to oversee the storage and movement of goods within a warehouse, as well as the management of inventory levels. According to a report by Logistics Management, companies that implement robust warehouse management systems can see a 30% increase in inventory accuracy, leading to better decision-making and reduced operational costs.

The importance of effective warehouse management cannot be overstated. A well-organized warehouse not only streamlines order fulfillment but also minimizes errors and fulfillment time. The report by the Warehousing Education and Research Council indicates that addressing warehouse inefficiencies can reduce operational costs by up to 25%. Additionally, effective inventory management allows businesses to maintain optimal stock levels, preventing both stockouts and overstock situations, which can be costly in terms of lost sales and excess carrying costs.

As businesses seek to remain competitive in an increasingly demanding market, investing in warehouse management tools becomes essential. These tools provide real-time data analytics, enabling companies to make informed decisions and respond swiftly to market changes. By adopting advanced warehouse management strategies, businesses can significantly improve their operational efficiency and enhance customer satisfaction.

Implementing a warehouse management tool can significantly enhance operational efficiency in businesses that rely on inventory management. One of the primary benefits is improved inventory accuracy. By utilizing real-time data tracking and automated systems, companies can minimize errors associated with manual entry and ensure that inventory counts are current. This accuracy not only streamlines order fulfillment but also reduces the likelihood of stockouts or overstock situations, leading to optimized inventory levels.

Another key advantage of a warehouse management tool is enhanced visibility across the supply chain. With a centralized system, businesses can easily monitor stock movement, track shipments, and analyze performance metrics. This level of visibility allows for better decision-making, enabling companies to respond rapidly to changing demands and streamline their logistics operations. Additionally, improved communication between different departments and stakeholders within the supply chain fosters collaboration, ultimately leading to increased productivity and operational efficiency.

When choosing a warehouse management system (WMS), it's essential to focus on features that enhance efficiency and streamline operations. One of the most critical components is real-time inventory tracking. This feature allows businesses to monitor stock levels constantly, reducing the risk of overstocking or stockouts. Another vital aspect is the integration capability with existing systems, such as accounting or order management software. This integration ensures that information flows seamlessly between departments, enhancing collaboration and decision-making.

Tips: Consider opting for a WMS that offers customizable reporting tools. This feature enables you to generate insights tailored to your specific needs, such as order fulfillment rates or inventory turnover, ultimately improving strategic planning.

Additionally, automated picking and packing functionality can significantly speed up the fulfillment process. This feature reduces human error and minimizes the time spent on manual tasks, allowing staff to focus on more critical responsibilities. A user-friendly interface is also important, as it minimizes training time and helps staff adapt quickly to the new system.

Tips: Look for a WMS that includes mobile access. This functionality allows warehouse staff to access information on the go, facilitating quicker decision-making and on-the-spot adjustments.

Efficient warehouse management is critical to enhancing supply chain performance. According to a study by the Warehousing Education and Research Council (WERC), organizations that implement advanced warehouse management systems experience a 25% reduction in operational costs and a 20% increase in order fulfillment speed. These improvements stem from better inventory tracking, streamlined processes, and enhanced communication among teams. In a landscape where 73% of supply chain leaders identify inefficient processes as a top barrier to productivity, investing in a comprehensive warehouse management tool can mitigate these challenges significantly.

To optimize warehouse operations, consider these tips:

First, regularly analyze inventory turnover rates to ensure that stock levels align with demand. This not only helps in minimizing holding costs but also streamlines order picking and shipping processes.

Second, train staff on best practices in using warehouse management software effectively, which can lead to improved accuracy and productivity.

Last, implement data analytics to monitor key performance indicators (KPIs); this will allow businesses to make informed decisions based on real-time information, thus enhancing overall supply chain efficiency.

Continuing to leverage technology in warehouse operations ultimately leads to a more agile and responsive supply chain.

In the competitive landscape of modern business, the implementation of warehouse management solutions has proven to be a game changer for many organizations. One prominent case study is that of a mid-sized retail company that faced challenges with inventory accuracy and order fulfillment speed. By integrating a warehouse management tool, the company saw a 30% reduction in order processing time and a significant increase in inventory visibility. This transformation not only streamlined operations but also enhanced customer satisfaction, as clients received their orders promptly and accurately.

Another compelling example comes from a logistics provider that serviced multiple industries but struggled with managing diverse inventories and fluctuating demands. After adopting a comprehensive warehouse management system, they were able to optimize storage space and improve picking efficiency. The tailored solution allowed them to implement real-time data tracking and analytics, leading to better decision-making and a notable decrease in operating costs. As a result, the company not only improved its overall efficiency but also positioned itself as a leader in the logistics sector, capable of responding swiftly to market demands.