+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the fast-paced world of warehousing, efficiency is crucial. Experts emphasize the significance of advanced systems. John Smith, a leading authority on logistics technology, states, "The Vertical Lift Carousel transforms storage and retrieval processes." This innovation optimizes space and enhances productivity.

Vertical Lift Carousels are automated systems. They consist of stacked trays, which rotate vertically. This design minimizes the travel distance for goods. Operators can access items quickly. However, improper implementation can lead to challenges.

Training staff effectively is essential. Misunderstandings about operations might occur. Some warehouses overlook maintenance practices, risking downtime. By addressing these issues, organizations can maximize the benefits of the Vertical Lift Carousel. Adapting to this technology requires continuous learning and adjustments.

Vertical lift carousels are gaining traction in warehousing for their efficiency. They save space, boost picking speed, and reduce labor costs. According to industry data, these systems can improve picking accuracy by up to 99%. This accuracy contributes to higher customer satisfaction. When managing inventory, this technology minimizes the time spent searching for items.

Warehouse operations often face challenges like limited space and high labor costs. Vertical lift carousels address these with compact designs that utilize vertical space. A report indicated that these systems can increase storage capacity by 50%. However, maximizing their potential requires staff training. Without proper knowledge, workers may struggle to adapt.

Also, some warehouses may see a slow return on investment. Initial costs can be high. There's a learning curve involved. It's crucial to evaluate specific warehouse needs before implementation. Not all operations will benefit equally. Recognizing these factors is key to making informed decisions.

When considering the implementation of vertical lift carousels in warehousing, several key factors come into play. The layout of your warehouse is crucial. According to a 2022 industry report, optimizing space can increase storage capacity by up to 50%. Vertical lift carousels save space by utilizing vertical storage. However, this solution may not fit all warehouse designs, particularly in older facilities.

Another vital factor is inventory management. Implementing vertical lift carousels can double the speed of picking operations. A recent survey indicated that 65% of warehouses report improved efficiency with this technology. Yet, integrating new systems can be challenging. Staff training is essential, as gaps in understanding can hinder performance. Without proper training, operators might struggle with the technology, leading to errors and reduced productivity.

Finally, maintenance considerations cannot be overlooked. Regular upkeep of vertical lift carousels is necessary. A study revealed that poorly maintained systems can reduce operational efficiency by as much as 30%. It's important to plan for routine checks and repairs. Neglecting this aspect could lead to costly downtime, ultimately impacting overall warehouse productivity. Balancing these key factors will help ensure a successful implementation of vertical lift carousels.

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Evaluate Space Requirements | Optimal use of vertical space. |

| 2 | Consider Workflow Efficiency | Reduced picking times. |

| 3 | Integration with WMS | Streamlined inventory management. |

| 4 | Train Staff Adequately | Improved safety and efficiency. |

| 5 | Implement Safety Protocols | Minimized risk of accidents. |

| 6 | Regular Maintenance Checks | Prolonged equipment lifespan. |

| 7 | Optimize Load Distribution | Prevent equipment strain. |

| 8 | Assess Picking Patterns | Increased operational efficiency. |

| 9 | Customize Storage Solutions | Better inventory control. |

| 10 | Monitor Performance Metrics | Data-driven improvements. |

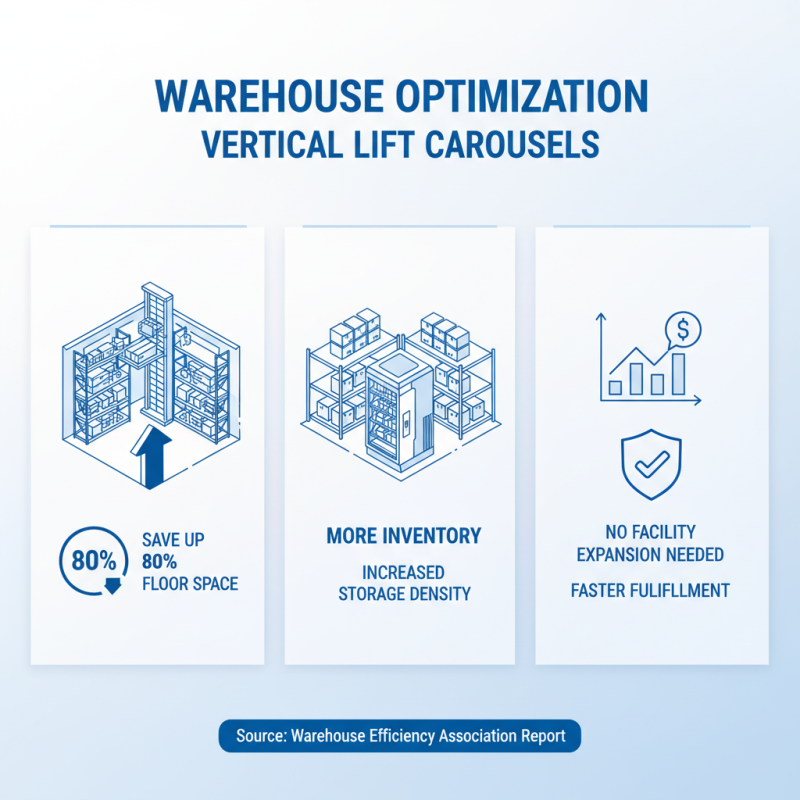

Vertical lift carousels have become essential in optimizing warehouse space. According to a report by the Warehouse Efficiency Association, businesses can save up to 80% in floor space when using these systems. This space savings allows for more inventory to be stored without needing to expand the facility. Many warehouses report increased storage density by reorganizing their layouts with carousels.

However, not all facilities utilize these systems effectively. A study indicated that 30% of warehouses fail to maximize the potential of vertical lift carousels due to poor organization. Inadequate training can lead to operational inefficiencies and inventory management issues. Proper staff training is crucial for utilizing these systems effectively.

Moreover, maintenance is often overlooked. Regular inspections and upkeep are essential to ensure consistent performance. Neglecting this aspect can lead to breakdowns and downtime. Therefore, focusing on both training and maintenance is vital for improving performance and space efficiency. Overall, careful planning and execution can yield significant benefits in warehousing operations.

Regular maintenance of vertical lift carousels is crucial for optimal performance in warehousing operations. A significant percentage—around 70%—of operational disruptions arise from equipment failures. Scheduled inspections can greatly reduce these issues. A study from the Automated Storage and Retrieval Systems Association indicates that well-maintained systems improve productivity by up to 30%.

Routine checks should focus on key components like drive systems and limit switches. Neglecting these areas can lead to unexpected breakdowns. For instance, worn-out bearings may compromise performance, leading to delays in order fulfillment. Proper lubrication and timely part replacements are simple yet essential tasks that can boost system longevity.

Another important aspect is operator training. Undertrained personnel may mismanage the equipment or overlook maintenance tasks. This can result in costly repairs or even workplace accidents. It's not just about fixing problems; it’s about proactive measures. Regular maintenance schedules can create a more efficient and safer warehouse environment, but they require commitment and accountability.

Training staff for the effective operation of vertical lift carousels is essential in modern warehouses. These systems improve efficiency by saving space and time. Yet, without proper training, mistakes can happen. Staff must understand the mechanics of the carousel. They should learn how to load and unload items correctly. A focus on safety is crucial: employees need to know the potential hazards involved.

Incorporating hands-on training sessions can be beneficial. These sessions allow staff to familiarize themselves with the equipment. Role-playing scenarios help them navigate challenges. Additionally, short instructional videos can serve as handy references. However, it’s vital to acknowledge that some may struggle initially. Regular feedback sessions can address specific concerns. Encouraging an open dialogue fosters continuous improvement.

Monitoring performance after training is equally important. Observing staff can reveal areas needing reinforcement. Adjustments in training methods might be necessary for better understanding. Continual assessment contributes to effective operations, ensuring everyone is on the same page. Remember, a well-trained team directly impacts productivity and safety. Adjusting training approaches based on team performance can lead to greater efficiency in warehousing operations.