+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

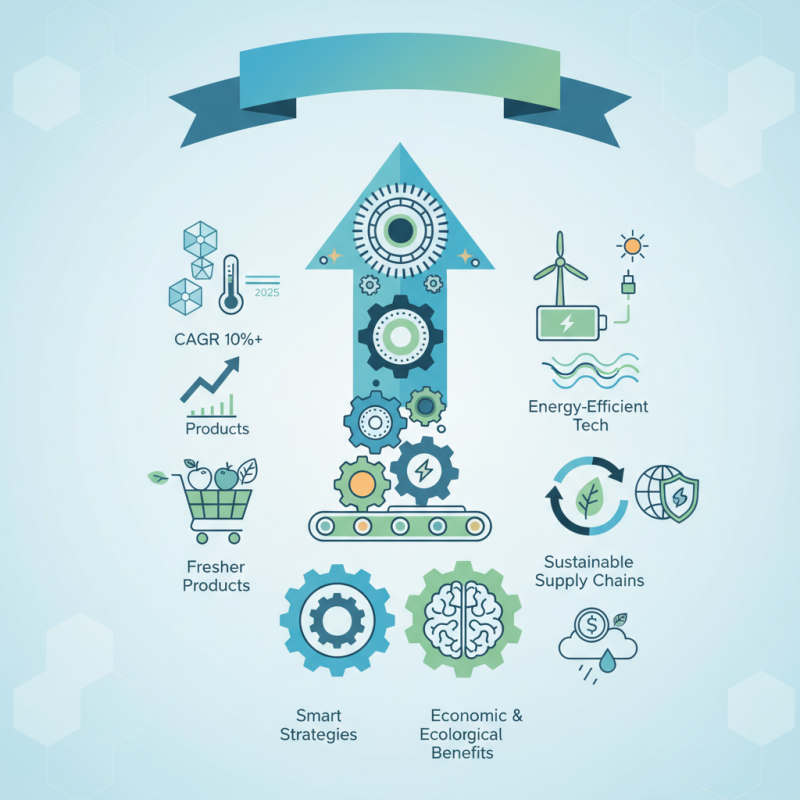

In the rapidly evolving landscape of logistics and supply chain management, optimizing Central Cold Storage has emerged as a critical focus for companies aiming to improve efficiency and achieve substantial cost savings. According to a recent study by the Global Cold Chain Alliance, the demand for cold storage facilities is projected to grow at a compound annual growth rate (CAGR) of over 10% through 2025. This surge is driven by the increasing need for preserving perishable goods, as consumer preferences shift toward fresher products. As industries, particularly food and pharmaceuticals, pivot towards more sustainable practices, leveraging technology to enhance Central Cold Storage processes will prove indispensable.

Expert insights emphasize the importance of innovation in this sector. Dr. Emily Stroud, a leading authority on cold chain logistics, states, "Adopting advanced monitoring systems and energy-efficient technologies in Central Cold Storage is not just an operational upgrade; it’s a decisive move towards sustainable supply chains." This sentiment resonates with industry professionals who recognize that optimizing these facilities can lead to significant reductions in energy consumption and operational costs. By focusing on these strategies, stakeholders can not only capitalize on cost savings but also play a pivotal role in addressing the growing environmental concerns associated with cold storage operations. Insights from the industry highlight that the future of logistics heavily relies on smart strategies to enhance Central Cold Storage efficiency, driving both economic and ecological benefits for businesses worldwide.

Central cold storage systems play a critical role in preserving perishable goods, particularly in industries such as food service, pharmaceuticals, and agriculture. These systems are designed to maintain optimal temperature conditions, thus extending the shelf life of products and ensuring safety and compliance with health regulations. According to a recent industry report, the demand for centralized cold storage is expected to grow by 15% annually, driven by the increasing need for efficient supply chain management and food safety standards. Understanding the various components, such as refrigeration technology, insulation materials, and monitoring systems, is essential for optimizing performance and energy efficiency.

Efficiency in central cold storage can be significantly enhanced by adopting advanced management systems and energy-efficient technologies. For example, the installation of IoT-based monitoring solutions allows for real-time temperature tracking, leading to improved compliance with safety regulations and reduced spoilage rates by approximately 20%. Additionally, the integration of energy-efficient cooling methods, such as variable refrigerant flow (VRF) systems, can decrease energy costs by nearly 30%. These innovations not only support cost savings but also contribute to sustainability efforts within the industry, highlighting the importance of continuously evaluating and upgrading cold storage infrastructure to meet evolving standards and consumer expectations.

Optimizing central cold storage for efficiency and cost savings involves several key factors that significantly influence operations. The design and layout of the storage facility are crucial; a well-planned space can enhance workflow, minimize energy consumption, and streamline the storage process. Proper insulation materials and building techniques can help maintain temperature controls effectively, reducing the need for excessive cooling. Additionally, utilizing advanced technologies such as IoT sensors can provide real-time monitoring of temperature and humidity levels, allowing for immediate adjustments and preventing potential product spoilage.

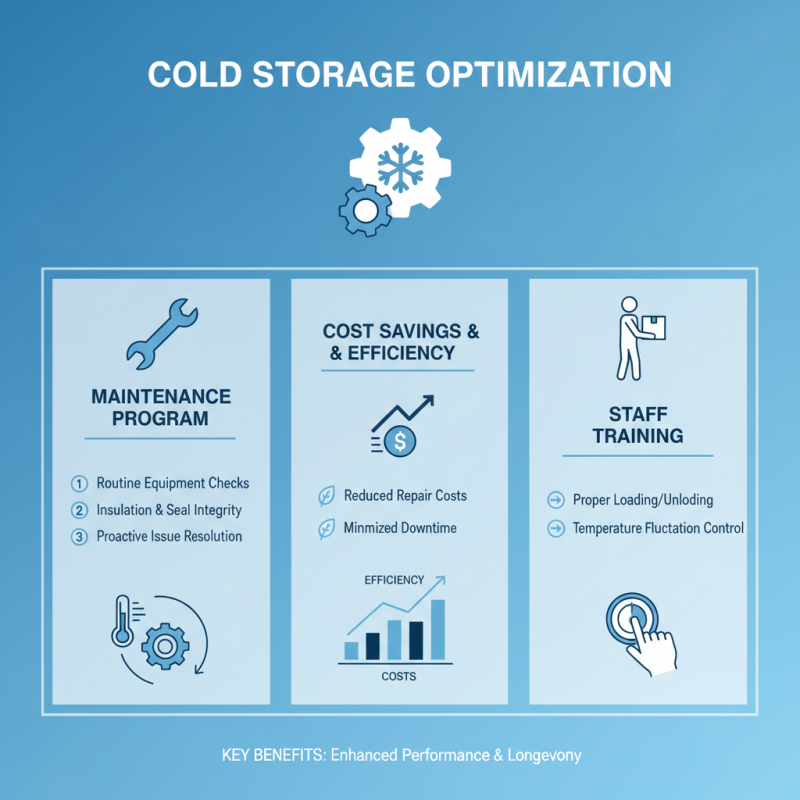

Another important aspect is inventory management. Implementing a robust inventory tracking system ensures optimal stock levels, reducing waste due to overstocking or product expiry. Techniques such as FIFO (First In, First Out) can help maintain the quality of perishable goods while optimizing storage space. Furthermore, regular maintenance of cooling equipment and systems is essential; scheduled check-ups can identify inefficiencies and prevent costly breakdowns. Training staff in best practices for handling and storing materials not only promotes efficiency but also fosters a culture of responsibility towards operational sustainability, ultimately leading to significant cost savings over time.

In recent years, optimizing central cold storage has become essential for businesses seeking to improve efficiency and reduce costs. According to a report by the International Institute of Refrigeration, improving cold storage operations can lead to a reduction in energy consumption by up to 30%. Implementing advanced technologies such as IoT sensors and AI-driven analytics allows for real-time monitoring of temperature and humidity levels, ensuring optimal conditions for products and significantly minimizing spoilage rates. Additionally, automation in the form of robotic systems can streamline stock management and order fulfillment, resulting in faster turnaround times and reduced labor costs.

**Tips:** Consider integrating IoT devices to track storage conditions continuously. This data can alert operators to any irregularities, permitting swift action and reducing waste.

Furthermore, energy-efficient refrigeration systems are becoming increasingly viable, with technologies such as variable speed compressors and enhanced insulation materials playing pivotal roles. A study by the U.S. Department of Energy indicates that adopting these technologies in cold storage facilities can save businesses up to $20 billion annually in energy costs alone. Moreover, adopting sustainable practices, like utilizing renewable energy sources, not only supports cost savings but also aligns with growing consumer demand for greener operations.

**Tips:** Regular maintenance of refrigeration units is critical to maintaining efficiency. Schedule periodic inspections to ensure systems operate at peak performance.

Effective energy management in cold storage facilities is essential for optimizing efficiency and reducing operating costs. One key practice is implementing advanced temperature monitoring and control systems. These technologies enable facility managers to maintain precise temperature settings, ensuring that products are stored at optimal conditions while minimizing energy waste. Automated systems can also adjust temperatures based on real-time data, responding to fluctuations in external conditions or product load to maximize efficiency.

Another best practice is to incorporate energy-efficient equipment and sustainable design principles. Utilizing LED lighting, high-efficiency refrigeration units, and proper insulation can significantly decrease energy consumption. Additionally, integrating renewable energy sources, such as solar panels, can further enhance sustainability and reduce reliance on grid power. Regular maintenance and retrofitting of existing equipment can also lead to substantial energy savings, ensuring that all systems operate at peak performance while extending their lifespan. These strategies not only lower costs but also contribute to a more environmentally friendly cold storage operation.

| Dimension | Best Practices | Expected Savings (%) | Implementation Timeframe |

|---|---|---|---|

| Energy-efficient Refrigeration Systems | Upgrade to high-efficiency units, utilize variable speed drives | 15-20% | 6-12 months |

| Insulation Improvement | Enhance wall and ceiling insulation, seal leaks | 10-15% | 3-6 months |

| Temperature Monitoring Systems | Implement IoT sensors for real-time data | 5-10% | 1-2 months |

| Regular Maintenance | Establish routine checks and service schedules | 8-12% | Ongoing |

| Energy Audits | Conduct regular audits to identify inefficiencies | 5-15% | 1-3 months |

Regular maintenance and optimization of cold storage systems are crucial for maximizing efficiency and ensuring cost savings. One effective strategy is implementing a scheduled maintenance program, which includes routine checks of refrigeration equipment, insulation integrity, and door seals. By addressing minor issues before they escalate, facilities can avoid costly repairs and downtime. Furthermore, training staff on best practices for loading and unloading can minimize temperature fluctuations and enhance system performance.

Another important aspect is the use of smart technology for monitoring and optimization. Integrating Internet of Things (IoT) devices allows for real-time monitoring of temperature and humidity levels, enabling operators to identify and resolve inefficiencies promptly. Data analytics can provide insights into usage patterns and help tailor operational schedules for peak efficiency. Additionally, embracing energy-efficient practices, such as optimizing airflow and using LED lighting, can significantly reduce energy consumption and further drive down operational costs.