+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the rapidly evolving landscape of logistics and supply chain management, optimizing operations within a Racked Warehouse has become paramount for enhancing efficiency and reducing operational costs. Recent industry reports indicate that effective warehouse layout and design can contribute to a staggering 25% increase in productivity, particularly in sectors where space utilization is critical. As global e-commerce continues to grow, projected to reach $6.4 trillion by 2024 according to Statista, the demand for optimized storage solutions becomes even more pronounced.

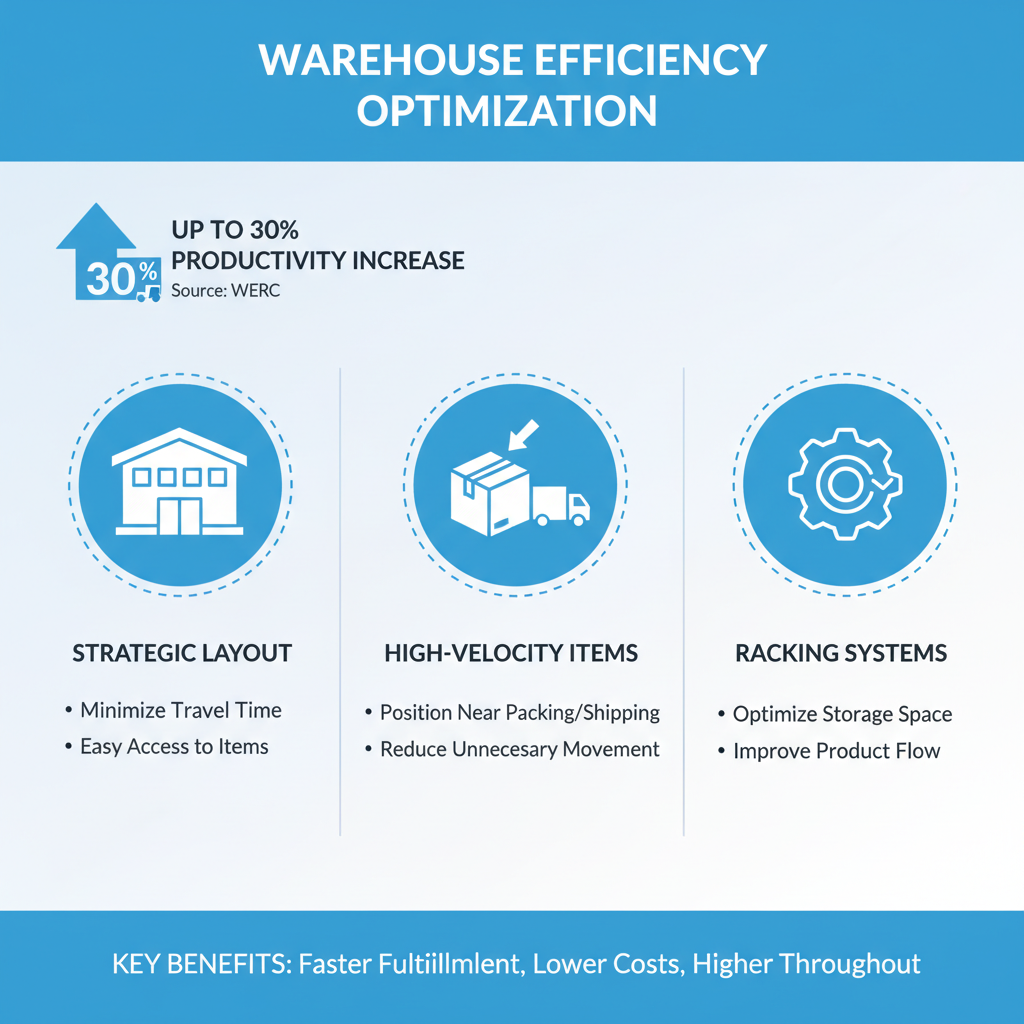

A well-structured Racked Warehouse not only maximizes storage density but also streamlines inventory management processes, paving the way for faster order fulfillment and improved customer satisfaction. Research from the Warehousing Education and Research Council (WERC) highlights that companies adopting advanced racking systems can enhance their picking accuracy by up to 30%, showcasing the direct relationship between warehouse optimization strategies and operational performance. As businesses strive to meet the complexities of modern supply chains, understanding the significant implications of warehouse design and efficiency will be crucial to maintaining competitive advantages in the marketplace.

In 2025, the importance of warehouse optimization cannot be overstated as businesses strive to remain competitive in an increasingly dynamic market. Efficiently organized warehouses not only reduce costs but also enhance service levels. By utilizing advanced technologies like artificial intelligence and IoT, companies can streamline their processes, improving accuracy in inventory management and reducing order fulfillment times. This shift towards smarter warehousing helps businesses respond quickly to customer demands, creating a more agile supply chain.

Moreover, optimizing a racked warehouse involves not just technology but a comprehensive review of layout and design. Implementing strategic shelving solutions allows for better space utilization and easy access to products. Additionally, employee training plays a crucial role in ensuring that the optimized systems are used effectively. As companies adapt to changing consumer behaviors and expectations in 2025, investing in warehouse optimization emerges as a fundamental strategy for driving efficiency and fostering growth.

This chart illustrates various optimization strategies implemented in warehouses in 2025, highlighting their effectiveness in improving efficiency.

When evaluating your current warehouse layout and racking systems, it is vital to consider how these elements contribute to overall efficiency. According to the Warehousing Education and Research Council (WERC), optimizing storage can increase productivity by up to 30%. A well-structured layout should minimize travel time and ensure that high-velocity items are easily accessible. This can be achieved by implementing a layout that strategically positions frequently picked products close to packing and shipping areas, thereby reducing unnecessary movement.

In addition to layout, the choice of racking systems plays a crucial role in maximizing storage capacity and operational efficiency. According to a report by Peerless Research Group, 82% of warehouses are now utilizing automated storage and retrieval systems (AS/RS) to enhance their inventory management processes. These systems can increase inventory accuracy and decrease retrieval time, with some facilities reporting improvements in order fulfillment rates by as much as 90%. Evaluating and updating racking systems to incorporate AS/RS can significantly transform warehouse operations, leading to improved efficiency and reduced operational costs.

In today's fast-paced business environment, implementing advanced

inventory management techniques is crucial for optimizing the efficiency of racked warehouses. Such techniques not only

streamline warehouse operations but also enhance inventory accuracy and visibility. Effective inventory management solutions

help in minimizing excess stock and ensuring that the right products are at the right place at the right time,

ultimately reducing operational costs.

Moreover, leveraging advanced technologies

like artificial intelligence and real-time supplier collaboration can significantly boost warehouse performance.

For instance, integrating AI can automate repetitive tasks, optimize workflows, and provide valuable insights into inventory levels.

This allows organizations to respond quickly to market changes, enhances their agility, and improves

overall supply chain resilience. By focusing on advanced inventory strategies,

warehouses can enhance their efficiency, reduce waste, and achieve a more profitable operation.

In 2025, optimizing warehouse operations through technology solutions is more crucial than ever. The integration of automation and artificial intelligence addresses complex supply chain challenges, enhancing efficiency and reducing operational costs. According to industry reports, about 65% of warehouses are expected to implement some form of automation by 2025, significantly impacting labor productivity and cost reduction. Solutions such as robotics and smart automation streamline workflows and improve scalability. These advancements allow organizations to process shipments faster while minimizing manual errors and labor strain.

Furthermore, artificial intelligence is transforming the landscape of operations management. Research shows that AI can improve inventory accuracy by 20% and reduce logistics costs by up to 15%. Companies adopting AI-driven tools for predictive analytics can anticipate demand fluctuations, thus optimizing stock levels and reducing waste. As organizations explore these 10 key trends in warehouse management, integrating advanced technologies will be essential for future growth and operational excellence. Embracing these innovations not only boosts efficiency but also sets the stage for sustainable practices in supply chain management.

| Dimension | Current Value | Target Value (2025) | Technology Solution |

|---|---|---|---|

| Average Order Processing Time | 30 minutes | 10 minutes | Automated Picking System |

| Inventory Accuracy | 85% | 99% | RFID Tracking |

| Warehouse Space Utilization | 60% | 85% | High-Density Racking System |

| Returns Processing Time | 5 days | 2 days | Returns Management Software |

| Employee Efficiency | 75 items/hour | 120 items/hour | Warehouse Management System (WMS) |

Training staff on best practices is essential for enhancing productivity in warehouse operations. As reported, AI technologies are revolutionizing operations management by streamlining processes, reducing costs, and improving overall efficiency. To leverage these advancements, it's crucial to equip warehouse employees with the skills to effectively utilize AI tools and automated systems. According to industry studies, training programs that focus on integrating technology into daily tasks lead to a 25% increase in productivity.

Moreover, implementing a structured training regime that highlights standard operating procedures can reduce operational lapses by up to 30%. In the wake of growing e-commerce demands, optimizing warehouse processes is more critical than ever. For instance, as online sales continue to surge, ensuring that staff are well-versed in the latest safety protocols and automated workflows directly impacts delivery times and customer satisfaction. By prioritizing comprehensive staff training, warehouses not only enhance efficiency but also foster a safer and more productive work environment.