+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In today's fast-paced industrial environment, the need for increased efficiency and reduced operational costs is more pressing than ever. One powerful strategy that organizations can adopt to achieve these goals is through the implementation of Rack Automation. This cutting-edge approach not only streamlines processes but also maximizes resource utilization, leading to significant time and cost savings. As companies strive to stay competitive, understanding and leveraging Rack Automation becomes crucial for optimizing workflows and enhancing productivity.

The importance of Rack Automation cannot be overstated; it revolutionizes how materials and goods are organized, accessed, and managed within facilities. By integrating automated systems within their rack structures, businesses can eliminate manual errors, reduce labor costs, and enhance inventory accuracy. This transition towards automation presents numerous opportunities to refine logistics and supply chain operations, ultimately driving growth and profitability. In this article, we will explore the top 10 rack automation tips that can help organizations harness this technology effectively, paving the way for operational excellence while minimizing expenses.

In today's fast-paced logistics environment, rack automation has emerged as a crucial factor in enhancing operational efficiency within modern warehousing. By implementing automated storage and retrieval systems, businesses can significantly streamline their inventory management processes. This technology minimizes the time spent on manual labor, allowing staff to focus on higher-level tasks, which in turn boosts overall productivity. With faster retrieval times and optimized storage solutions, warehouses can handle increased throughput without the need for substantial physical expansion.

Moreover, the key benefits of rack automation extend beyond just efficiency. Cost reduction is one of the most substantial advantages, as automated systems can lower labor costs and reduce the risk of errors associated with manual handling. With improved accuracy in inventory control and order fulfillment, companies can also decrease excess inventory and minimize waste, fostering a more sustainable supply chain. As warehouses increasingly adopt these advanced technologies, they not only enhance their operational capabilities but also gain a competitive edge in the market, leading to long-term financial savings and improved service levels.

Efficient rack automation systems are essential for optimizing warehouse operations and significantly reducing costs. Recent reports indicate that businesses implementing automated systems in their warehouses can achieve up to a 30% increase in operational efficiency. Key technologies driving this transformation include advanced robotics, artificial intelligence (AI), and the Internet of Things (IoT). These innovations allow for real-time data processing, which streamlines inventory management, reduces labor costs, and minimizes the likelihood of errors in stock handling.

For instance, AI-powered robots can manage tasks ranging from sorting to transporting goods within the facility, while IoT devices offer seamless connectivity between different operations, ensuring that inventory levels are always accurate. According to a study by the Warehousing Education and Research Council (WERC), integrating automation technologies can lead to up to a 25% reduction in operational costs over time. Furthermore, automation provides valuable analytics that help organizations make more informed decisions about inventory turnover and space utilization, further enhancing productivity and cost savings in the long run. Embracing these essential technologies is not just a trend but a strategic necessity for organizations aiming to thrive in an increasingly competitive marketplace.

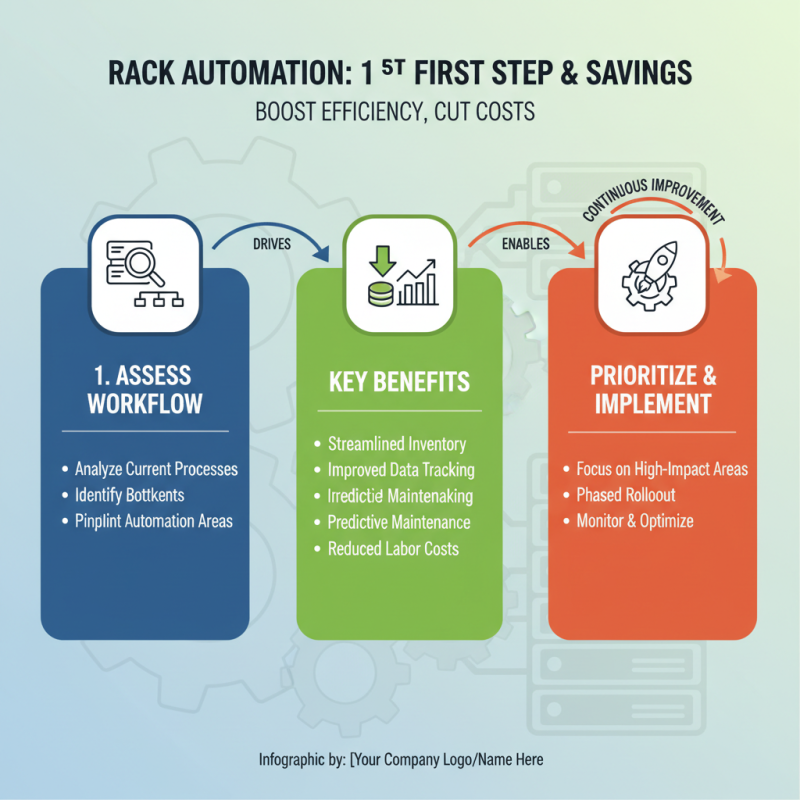

Implementing rack automation solutions can significantly enhance operational efficiency and drive down costs in various industries. The first step in this process is conducting a thorough assessment of your current operational workflow. Analyze existing processes to identify bottlenecks and areas where automation could streamline tasks, such as inventory management, data tracking, or equipment maintenance. This evaluation will not only highlight the potential benefits of rack automation but also help prioritize areas that require immediate attention.

Once you have a clear understanding of your operations, the next stage involves selecting the appropriate automation technologies that align with your needs. Explore various solutions like automated storage and retrieval systems, robotic arms, or smart warehouse management software. It’s crucial to evaluate each option’s scalability, integration capabilities, and ease of use. After choosing the right technology, develop a detailed implementation plan that includes timelines, milestones, and employee training to ensure a smooth transition. Engaging your team through workshops and hands-on training will foster acceptance of the new system, making it easier to incorporate automation into daily operations.

Implementing rack automation can significantly enhance operational efficiency, but organizations often encounter various challenges in the process. One of the most common hurdles is the initial integration of automation systems with existing infrastructure. Many facilities may operate with outdated equipment, making it difficult to seamlessly connect new automated solutions. To tackle this, businesses should conduct a thorough assessment of their current systems and invest in necessary upgrades or modifications, ensuring that new automation tools can be effectively integrated without disrupting ongoing operations.

Another frequent challenge lies in employee adaptation to automated environments. Workers may be hesitant or resistant to change, worrying that automation will replace their jobs. To overcome this, companies should focus on comprehensive training programs that highlight the benefits of automation, not only for the organization but also for the employees themselves. Engaging staff in the automation process by soliciting their feedback and involving them in decision-making can foster a more positive atmosphere around automation. By addressing these common challenges with proactive strategies, organizations can maximize the benefits of rack automation, ultimately leading to increased efficiency and reduced costs.

Measuring success in rack automation requires an understanding of key metrics that can provide insights into operational efficiency and cost-effectiveness. One of the most critical metrics is throughput, which measures the number of items processed within a set time frame. Higher throughput indicates a smoother operation and optimal use of automated systems. Additionally, analyzing cycle time will help identify bottlenecks in the process, allowing teams to make necessary adjustments to enhance efficiency.

To optimize rack automation, consider implementing these tips: First, conduct regular performance reviews of your automated systems to pinpoint areas that need improvement. Secondly, invest in employee training to ensure that staff members are proficient in utilizing the technology, which can lead to fewer errors and enhanced productivity. Lastly, maintain accurate inventory tracking systems to avoid excess stock, reducing holding costs and increasing turnover rates.

Other valuable metrics to evaluate include energy consumption and maintenance frequency of automation equipment. Lower energy consumption can lead to cost savings, while monitoring maintenance frequency can prevent downtime and extend the lifespan of your automated systems. By focusing on these metrics, businesses can refine their rack automation strategies, leading to improved efficiency and a healthier bottom line.