+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

A Racked Warehouse is a specialized storage solution designed to maximize space efficiency. This type of warehouse uses vertical racking systems to organize inventory. It allows for greater access and visibility of products.

In a Racked Warehouse, pallets and items are stored on shelves that reach high ceilings. This method optimizes floor space, enabling more goods to be stored in a smaller area. However, it requires careful planning. Each racking system must be suitable for the type of products stored.

The benefits are clear, yet challenges exist. Implementing a Racked Warehouse can involve high initial costs. Furthermore, employee training is essential to ensure safety and efficiency. Reflecting on these aspects helps businesses make informed decisions.

A racked warehouse is a specialized facility designed for efficient storage. It uses racks to store goods, maximizing vertical space. According to industry reports, up to 80% of warehouse space can be utilized through strategic racking systems. This method allows for better organization and access to products.

In a racked warehouse, different racking types exist. They include selective, drive-in, and pallet flow racks. Each type has unique advantages. For example, selective racks offer easy access but may waste some space. On the other hand, drive-in racks maximize density but complicate access. The choice depends on specific needs.

Implementing these systems requires careful consideration. A poorly designed layout could lead to wasted space and inefficient operations. A study found that warehouses with effective racking can reduce travel time by 25%. However, businesses often overlook the importance of proper training for staff in utilizing these systems. This oversight can result in costly mistakes.

Racked warehouses are specialized storage facilities designed for efficiency. They utilize a system of shelves and racks to maximize vertical space. These structures allow for a higher density of product storage. Adaptability is one of their key features. Different racking systems can accommodate various types of goods, from pallets to smaller items. Each method can change based on the inventory needs.

Another important aspect is accessibility. Racked warehouses often have aisles that facilitate easy navigation. Forklifts and pallet jacks are commonly used. This access speeds up the retrieval process. However, careful planning is crucial to avoid congestion. In some cases, layout impracticalities can lead to bottlenecks.

Safety remains paramount in a racked warehouse setup. Proper installation of racks ensures stability. Regular inspections are necessary. Issues often arise when racks are overloaded or improperly used. Staff training is essential. Educating employees on safe usage can prevent accidents. This is an ongoing challenge that requires constant attention and adjustment.

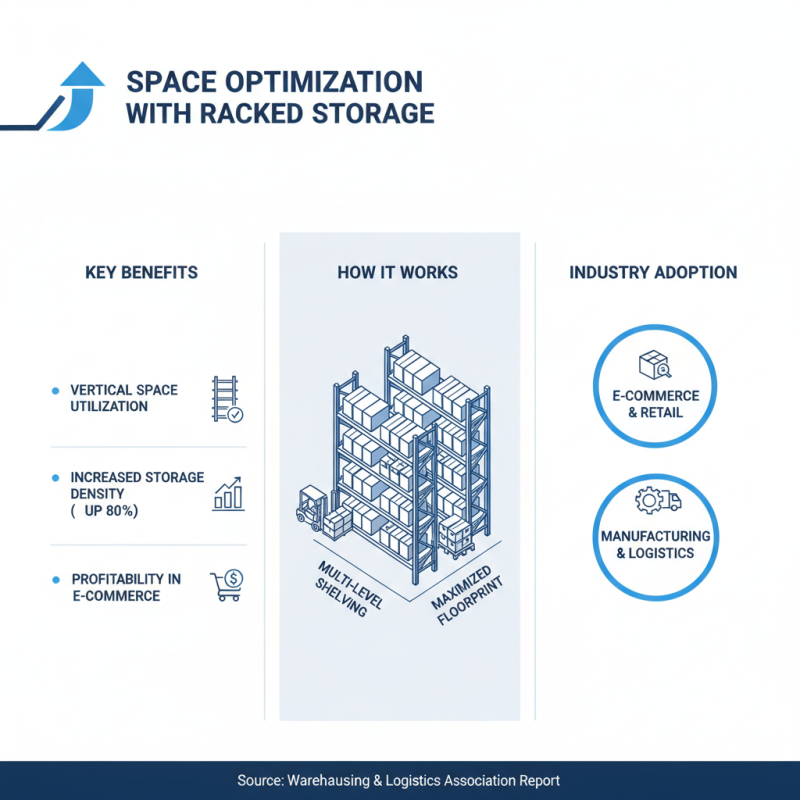

Racked storage solutions have gained traction in industries looking to optimize space. These systems use vertical levels to maximize storage capacity. According to a recent report by the Warehousing and Logistics Association, racked storage can increase storage density by up to 80%. This is significant in sectors like e-commerce, where space efficiency drives profitability.

Another study by the National Institute of Standards and Technology found that well-organized racked warehouses can enhance retrieval speed by as much as 25%. This efficiency leads to faster order fulfillment. However, not all warehouses are designed for racked solutions. Organizations must evaluate their specific needs before implementation. Poor planning can lead to wasted space or inaccessible inventory.

Racked storage also promotes better inventory management. It allows for clear visibility of stock levels. Yet, improper labeling or maintenance can result in lost items. Workers may struggle to locate products, illustrating the need for regular audits. Striking a balance between high-density storage and accessibility is crucial. Adopting racked systems may improve organization, but it requires continuous refinement to realize full benefits.

Racked warehouses utilize various systems to maximize storage efficiency. These racking systems allow businesses to organize inventory effectively. Common types include selective pallet racking. This popular method offers direct access to pallets. It can hold large volumes of goods in an orderly manner. However, it does have limitations in maximizing vertical space.

Another system is the drive-in racking. This design allows for high-density storage. Forklifts can drive into the racking structure to deposit or retrieve pallets. It's efficient for storing large quantities of similar items. The drawback is limited accessibility to individual pallets. While it increases capacity, it can complicate operations.

Lastly, there’s the cantilever racking. This system is ideal for long or bulky items. It provides clear visibility and easy access. However, if not used correctly, it can create safety hazards. It’s essential to train staff on safe loading and unloading. Each type has its pros and cons. The key is finding the right balance for optimal storage solutions.

Racked warehouses have gained popularity for their ability to maximize storage efficiency. Effective use of vertical space is crucial. According to the Warehousing Education and Research Council (WERC), poorly utilized space can cost businesses up to 30% in lost capacity. This statistic highlights the need for strategic planning in warehouse layouts.

Implementing adjustable racking systems can optimize space significantly. These systems allow for reconfiguration as business needs change. A recent report from the Material Handling Industry (MHI) indicates that businesses using such systems report a 20-30% increase in storage efficiency. Regularly reviewing product dimensions and turnover rates ensures that racking solutions remain effective.

However, some warehouses still struggle with layout issues. Overcrowding can lead to inefficiencies and even safety hazards. Implementing clear labeling and organization systems can help address these challenges. Ensuring that all staff understand the layout and storage protocols is essential. Good practices lead to better warehouse management and fewer accidents. Racked warehouses can drive productivity, but continuous improvement is necessary.