+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the ever-evolving landscape of logistics and supply chain management, the adoption of Warehouse Management System (WMS) software has emerged as a cornerstone for operational excellence. According to recent industry reports, organizations utilizing WMS solutions have experienced a remarkable 25% increase in inventory accuracy and a corresponding 30% reduction in order fulfillment times. This surge in efficiency underscores the pivotal role that WMS system software plays in modern warehousing, facilitating not just streamlined processes but also enhanced customer satisfaction.

As highlighted by industry expert Dr. John Smith, a recognized authority in warehouse automation, "Implementing WMS system software transforms how warehouses operate, promoting precision, scalability, and agility.” His insights emphasize the necessity for businesses to embrace cutting-edge technology to remain competitive. Moreover, the integration of WMS not only boosts productivity but also provides valuable data analytics that can inform strategic decisions and optimize resource allocation.

In light of these benefits, warehouses worldwide are increasingly turning to advanced WMS solutions. This shift not only results in operational savings but also positions companies to respond proactively to market demands. As we delve into the top ten advantages of adopting WMS system software, it becomes clear that the future of warehousing hinges on embracing these innovative tools.

Warehouse Management System (WMS) software plays a crucial role in enhancing the efficiency of warehouse operations. By automating and optimizing processes such as inventory management, order fulfillment, and shipping, WMS can significantly reduce operational costs and improve accuracy. According to a recent survey by the Warehousing Education and Research Council (WERC), companies that implement WMS solutions report a decrease in inventory errors by approximately 20% and a reduction in labor costs by up to 30%. This software not only streamlines workflows but also provides real-time visibility into inventory levels, enabling business leaders to make data-driven decisions.

Tips: To fully leverage the benefits of a WMS, ensure that your staff is adequately trained on the system's functionalities. A well-trained team can utilize the software to its maximum potential, leading to improved productivity and efficiency. Moreover, regularly reviewing your WMS performance metrics can highlight areas for improvement and adaptation, ensuring that your operations remain agile in a changing market.

Implementing WMS can also lead to quicker response times to customer demands. A report from the Council of Supply Chain Management Professionals (CSCMP) indicates that companies with a robust WMS can achieve a 25% faster order processing rate, meeting the rising expectations of consumers for speed and reliability. By staying ahead with the right technology, organizations can maintain a competitive edge in the fast-paced logistics landscape.

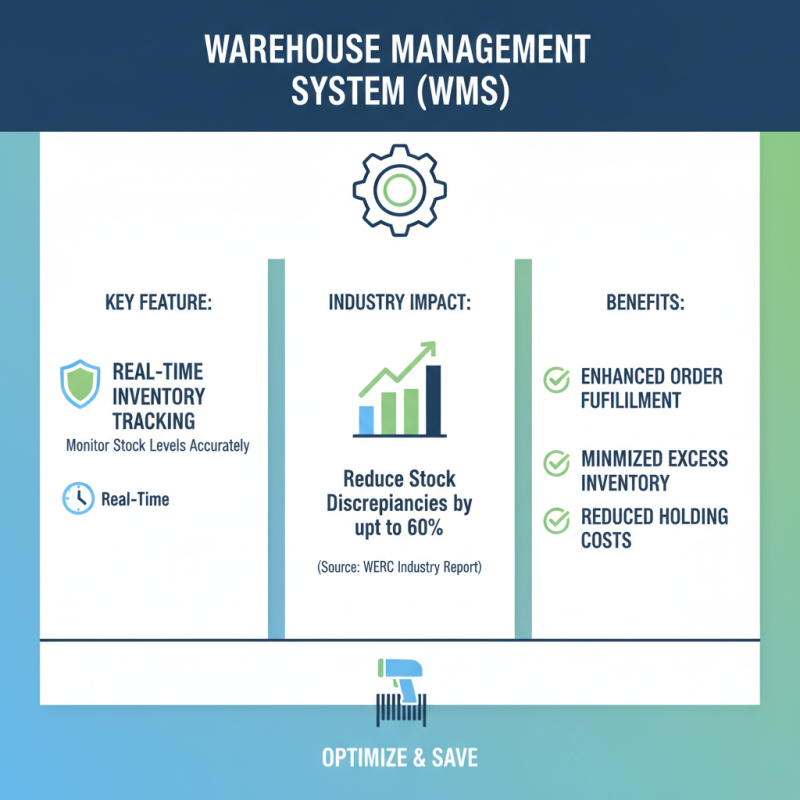

The Warehouse Management System (WMS) software has become essential in optimizing warehouse operations and enhancing efficiency. One key feature of WMS is real-time inventory tracking, which allows businesses to monitor stock levels accurately. According to a recent industry report by the Warehouse Education and Research Council, implementing real-time inventory systems can reduce stock discrepancies by up to 60%. This improvement not only enhances order fulfillment rates but also minimizes excess inventory, leading to reduced holding costs.

Another significant aspect of WMS software is its advanced analytics capabilities, which empower managers to make data-driven decisions. By analyzing key performance indicators (KPIs) such as pick rates and order accuracy, companies can identify bottlenecks in their processes. A survey by Logistics Management indicates that organizations leveraging WMS analytics have experienced up to a 20% increase in overall warehouse productivity.

**Tip:** When selecting a WMS, consider one that integrates seamlessly with your existing ERP system to ensure that data flows smoothly between platforms.

Moreover, automation features, such as automated picking, packing, and shipping processes, contribute significantly to enhanced efficiency. A study published in the Journal of Supply Chain Management suggests that warehouses employing automation see a reduction in labor costs by approximately 30%. Automating repetitive tasks not only reduces human error but also allows staff to focus on more strategic activities.

**Tip:** Always evaluate how scalable the WMS is, as this will allow your system to grow alongside your business and adapt to changing operational needs.

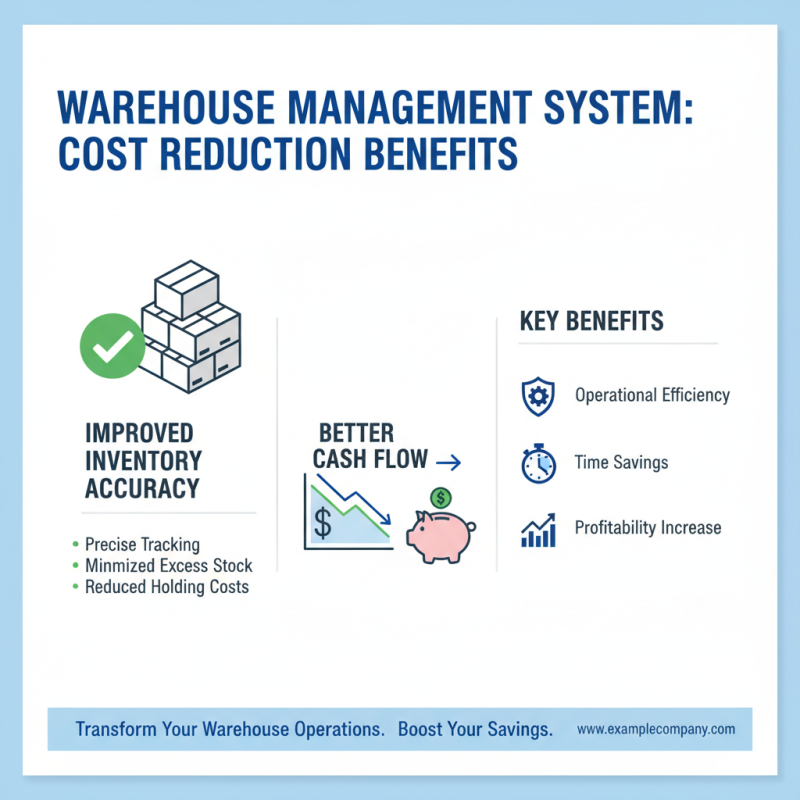

Implementing a Warehouse Management System (WMS) can lead to significant cost reductions for businesses engaged in warehouse operations. One of the most immediate financial benefits is the improvement in inventory accuracy. With precise tracking and management of stock levels, businesses minimize excess inventory and reduce holding costs. This streamlined inventory management means fewer resources are tied up in unsold goods, allowing for better cash flow and a more efficient allocation of financial resources.

Additionally, the automation capabilities offered by WMS can decrease labor costs by reducing the reliance on manual processes. By automating key functions such as order processing, picking, and shipping, warehouses can enhance operational efficiency while also lowering the risk of human error. This not only leads to faster fulfillment times but also helps allocate staff resources more effectively, shifting workers to higher-value tasks that contribute to overall productivity and profitability. As a result, businesses can see a significant reduction in operational costs, ultimately boosting their bottom line.

Warehouse Management System (WMS) software has become an essential tool for improving inventory management and accuracy in warehouse operations. According to a report by the Warehousing Education and Research Council (WERC), companies that utilize WMS have seen improvements in inventory accuracy by up to 99.9%. This remarkable level of precision arises from real-time tracking capabilities that WMS provides, enabling businesses to monitor inventory levels, movement, and locations seamlessly. Additionally, with automated processes, manual errors in stock management are significantly reduced, which not only conserves time but also minimizes costly discrepancies pertaining to overstocks or stockouts.

Moreover, the use of WMS contributes to optimized warehouse layouts and increased efficiency in order fulfillment. The 2021 MHI Annual Industry Report highlights that warehouses employing WMS solutions can enhance their picking accuracy by as much as 25%, driven by systematic organization and intelligent routing of products. Improved inventory management fosters better customer satisfaction as orders are processed more accurately and swiftly. Consequently, businesses can achieve higher service levels and maintain strong relationships with their customers, ultimately leading to increased sales and revenue growth. As the industry continues to evolve, investing in a WMS system has proven to be a strategic move for companies aiming to streamline their operations and stay competitive in the market.

The integration of Warehouse Management System (WMS) software with other supply chain solutions is crucial for modern warehouse operations. By creating a cohesive platform that connects various components such as transportation management systems (TMS), inventory management, and enterprise resource planning (ERP), organizations can achieve a significant boost in operational efficiency. According to a report from Gartner, companies that effectively integrate WMS with their supply chain solutions can realize up to a 25% reduction in operational costs due to improved accuracy in inventory tracking and fulfillment processes.

To maximize the benefits of WMS integration, it is essential to focus on data visibility across the supply chain. Streamlined information flow allows for real-time tracking of goods, enabling businesses to respond swiftly to market demands. Additionally, improved communication between departments enhances decision-making capabilities, leading to optimized inventory levels and decreased stockouts. Research from the Supply Chain Management Review indicates that organizations employing integrated systems see a 30% increase in order fulfillment rates.

**Tip:** To ensure a successful WMS implementation, conduct a thorough analysis of your existing technology infrastructure and identify areas where integration can yield the greatest improvements. Investing in training for staff on the integrated systems can also enhance operational competency and foster a culture of continuous improvement in warehouse practices.