+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the rapidly evolving landscape of logistics and supply chain management, optimizing space is crucial for enhancing operational efficiency in warehouses. According to a report by the Warehousing Education and Research Council (WERC), over 25% of warehouse operators cite inadequate space utilization as a significant challenge in their operations. As companies seek to streamline their processes, the design of a Warehouse Floor Plan plays a pivotal role in maximizing both space and productivity.

Experts like Dr. Emily Johnson, a renowned authority in warehouse optimization, emphasize that "a well-designed Warehouse Floor Plan can significantly reduce picking times and improve inventory accuracy." With advancements in technology and data analytics, the 2025 trends in warehouse layouts are gravitating towards modular designs that accommodate flexibility and scalability. Implementing innovative flooring strategies not only supports efficient inventory management but also enhances worker safety and satisfaction, making it a vital investment for businesses aiming to thrive in competitive markets.

As we delve into the top Warehouse Floor Plan ideas for 2025, it’s essential to consider these principles to achieve optimal space utilization while preparing for the future of warehousing. Addressing these needs is no longer just beneficial; it has become essential for companies to maintain a competitive edge.

Warehouse floor planning plays a critical role in optimizing space utilization, which directly impacts efficiency and productivity. A well-designed floor plan maximizes the available area while minimizing wasted space, allowing for smoother operations and easier access to goods. By understanding how to structure the layout based on the flow of materials and the needs of personnel, warehouses can achieve a more streamlined process.

Effective space utilization also involves considering the positioning of shelving, machinery, and workstations. This careful arrangement not only enhances workflow but also ensures safety and reduces the risk of accidents. Moreover, incorporating flexible design elements, such as movable shelving or modular work areas, can adapt to changing operational needs, further enhancing the overall functionality of the warehouse. By prioritizing thoughtful floor planning, companies can create an environment that not only meets current demands but is also capable of evolving with future requirements.

| Floor Plan Type | Description | Advantages | Space Utilization (%) |

|---|---|---|---|

| U-Shaped | Designed to create a circular workflow, allowing easy access to multiple areas. | Enhanced workflow, reduced travel time. | 85% |

| Straight-Line | Linear arrangement ideal for smaller warehouses, maximizing depth. | Simplified layout, easy inventory management. | 80% |

| Grid Layout | Organizes space into squares or rectangles, making access to products straightforward. | High visibility, efficient space management. | 90% |

| Dynamic Layout | Flexible design that allows for alterations based on changes in inventory. | Versatile and adapts to demand. | 75% |

| Cross Docking | Minimizes storage time, transferring goods directly from receiving to shipping. | Reduces handling time and storage costs. | 95% |

In 2025, optimizing warehouse space utilization will hinge on key metrics that drive efficiency and productivity. According to a report by the Warehousing Association, an efficient warehouse layout can reduce operational costs by up to 30%. Metrics such as space utilization rate, which measures the percentage of warehouse space actually used for storage versus total available space, will be crucial. A target space utilization rate of 85% is considered ideal for maintaining flow without compromising accessibility.

In addition, the throughput metric, which reflects the amount of product moving through the warehouse over a given period, will be integral in assessing operational efficiency. As highlighted in recent studies, warehouses that achieve a throughput increase of 15% year-over-year tend to adapt faster to market demands. Furthermore, tracking order accuracy rates—where a goal of 99% accuracy is standard—will be vital in maintaining customer satisfaction and operational reliability. These metrics will help warehouse managers to not only identify bottlenecks but also refine their space planning strategies to enhance overall effectiveness.

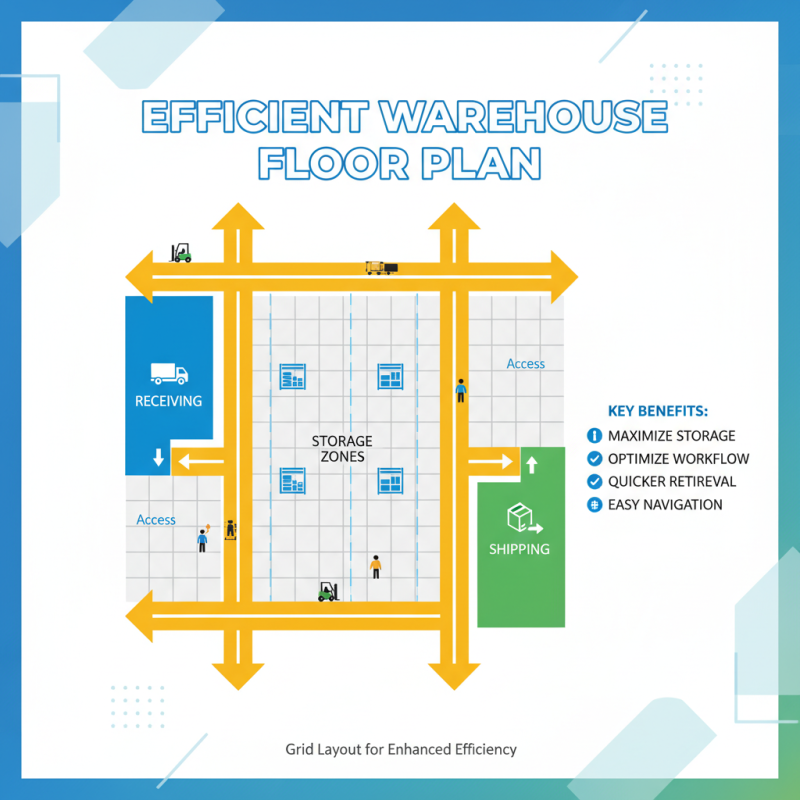

Creating an efficient warehouse floor plan is essential for maximizing both storage capacity and workflow efficiency. Innovative layout designs can significantly enhance the way products are organized and accessed, leading to quicker retrieval times and smoother operations. One effective strategy is the use of a grid layout that optimizes space by organizing storage areas in a manner that allows easy navigation and access to goods. By implementing clear aisles and designated zones, warehouses can facilitate a more systematic approach to inventory management, reducing the time workers spend searching for items.

Additionally, incorporating flexible shelving units can adapt to changing inventory needs, ensuring that storage solutions are not static but rather evolve with the demands of the business. For instance, modular shelving can be reconfigured to accommodate different sizes of products or heightened stock levels, providing versatility in storage while maintaining an orderly space. Moreover, integrating technology, such as automated guided vehicles (AGVs) and real-time inventory tracking systems, not only streamlines workflow but also minimizes human error, creating a more efficient environment conducive to maximizing overall productivity.

The integration of technology into warehouse design is revolutionizing the way space is utilized and managed. Automation and smart solutions not only enhance efficiency but also significantly improve layout flexibility. By employing automated guided vehicles (AGVs) or robotics for picking and sorting, businesses can free up valuable floor space previously occupied by workers and manual processes. This shift allows for a more streamlined workflow and increases the storage capacity of the warehouse, as aisles can be designed narrower without sacrificing accessibility.

To maximize the benefits of these innovative technologies, consider implementing a warehouse management system (WMS) that seamlessly integrates with automation tools. This system will provide real-time data on inventory levels and location, enabling optimal organization and retrieval strategies. Additionally, utilizing cloud-based technology can facilitate remote monitoring and control, allowing for swift adjustments as needs evolve.

**Tips:**

1. Regularly assess the layout of your warehouse to ensure it accommodates the latest automation technologies while maintaining efficient workflows.

2. Train staff on new technologies to maximize their potential and enhance overall operational efficiency. This ensures that everyone is on board with the new systems in place and can contribute to maximizing space utilization.

3. Invest in modular shelving and racking systems that can be easily reconfigured as your automation needs change, allowing for adaptive growth and efficient space usage.

Creating flexible floor plans in warehouse design is essential for adapting to the ever-changing market demands. One of the best practices involves implementing modular shelving and racking systems that can be reconfigured easily. This approach not only maximizes storage efficiency but also allows for quick adjustments in response to fluctuations in inventory types and volumes. By designing open spaces that can accommodate different activities, warehouses can transition smoothly from storage to staging or shipping, enhancing operational agility.

Another key consideration is the use of advanced technology in floor planning. Incorporating automated systems and smart inventory management solutions can optimize space utilization while providing real-time data on stock levels and space availability. This allows warehouse managers to make informed decisions about layout adjustments, ensuring that the design remains relevant in a dynamic environment. Regularly reviewing and analyzing floor plan performance can lead to ongoing improvements, making the warehouse more resilient to shifts in the market while maintaining efficiency in operations.